Vial material – the invisible success factor

The material properties of a vial play a strategically crucial role, as they can significantly impact the outcome of an analysis. While borosilicate glass remains the gold standard, providing an indispensable foundation of purity and chemical resistance, the increasing demands of modern applications - from high-throughput automation to sensitive biologics - have driven the development of highly specialized polymer alternatives. This article compares the key strengths and limitations of these material classes, establishing a foundation for selecting the most suitable option for each analytical application.

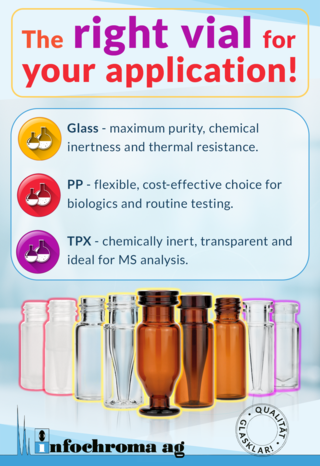

- Borosilicate glass: Gold standard due to being chemically inert and temperature resistant.

- Silanised glass & polypropylene: Both minimise protein adsorption with PP being a cost-effective alternative.

- Polymethylpentene (TPX): Transparent, chemically resistant high-performance option.

- Conclusion: Choosing vial material is a strategic desicion which should be based on the application.

Borosilicate glass is the gold standard in chemical and thermal stability

In applications such as organic chemistry, trace analysis, and high-temperature processes, borosilicate glass of hydrolytic class 1 remains the material of choice. Its stable, three-dimensional silicate network provides exceptional chemical inertness and withstands temperatures ranging from – 196 °C to over 300 °C. Uniquely, it enables dry-heat sterilisation above 250 °C, making it indispensable for pyrogen-free processes. The most notable limitation is imposed by its polar surface: free silanol groups (Si–OH) can cause adsorption of valuable protein and peptide samples through electrostatic interactions. In addition, borosilicate glass cannot be processed in standard recycling streams due to its high melting point and must be disposed of separately, even when free of chemical residues.

Silanised glass and polypropylene, a solution preventing protein adsorption

To mitigate protein adsorption, silanised glass provides a proven high-performance solution, while pharmaceutical-grade polypropylene (PP) provides a cost-effective alternative. Its inherently hydrophobic surface significantly reduces protein binding. However, this advantage requires knowledge of the analyte’s nature: while most proteins benefit, highly hydro-phobic peptides such as insulin or GLP-1 may exhibit greater affinity to PP than to glass. The mechanical flexibility of PP can absorb stress from repeated freeze–thaw cycles thereby preventing material fatigue, which is a particular advantage during aliquot handling. Nonetheless, its inherent limitations define its scope of application: the material is restricted to a temperature range of approximately – 20 °C to +135 °C, is unsuitable for aggressive organic solvents, and its milky appearance precludes use in optical analyses.

Polymethylpentene (TPX), a transparent high-performance alternative

Where the chemical or thermal resistance of PP proves insufficient, but a plastic solution is required, polymethylpentene (TPX) offers an advanced alternative. Transparent like glass yet more thermally stable than PP, TPX covers an application range from – 40 °C to +120 °C, with short term tolerance to up to 170 °C. Its chemical resistance surpasses that of PP, and its exceptionally inert adsorption behavior makes it the ideal choice even for the most demanding peptides in mass spectrometry. While it has a significantly higher breaking resistance than glass, at room temperature, it is harder and more brittle than the flexible PP, which requires conscious handling.

Conclusion

The choice of the adequate vial material is therefore a strategic decision. Borosilicate glass remains the universal standard for inertness, purity and thermal stability. For sensitive protein samples, silanised glass represents a high-performance solution, while poly-propylene (PP) offers a robust and economical alternative. While TPX positions itself as specialist material for demanding niche applications.

Choosing the right vial material requires sound application-specific expertise that goes far beyond product catalogues.

infochroma AG supports you individually with competent advice and samples.